Polyfunctional Robots: The Future of Versatility 2025

By Ankita Das

Polyfunctional Robots are emerging as transformative tools that redefine versatility and efficiency. Unlike traditional single-function robots, these advanced systems perform multiple tasks across diverse domains, adapting to changing environments and operational requirements. Powered by modular hardware, artificial intelligence (AI), and machine learning, polyfunctional robots are set to revolutionize manufacturing, healthcare, logistics, and domestic applications. This blog will explore the types of polyfunctional robots, their key components, and their industrial applications to shape the future of automation. Scroll down to gain a comprehensive understanding of how these robots are driving innovation and efficiency in 2025.

Understanding Polyfunctional Robots

A polyfunctional robot is an advanced robotic system engineered to execute multiple tasks without hardware reconfiguration or extensive reprogramming. The robotic technology is backed by AI-driven adaptability and supports real-time environmental interaction. It also transcends traditional single-function automation by integrating modular hardware. Unlike conventional robots, polyfunctional robots dynamically switch roles from assembling products to diagnosing machinery defects. For instance, a robot initially designed for warehouse logistics might autonomously adapt to disinfect hospital rooms during a health crisis. This versatility is achieved by leveraging embedded intelligence and interchangeable components, which enable them to adapt to new functions.

Key Components of Polyfunctional Robots

Polyfunctional robots achieve their versatility by integrating a range of cutting-edge technologies. These components work together to enable robots to adapt to diverse tasks and environments efficiently. Below is an in-depth look at the key components that make polyfunctional robots so effective:

1. Modular Hardware

Modular hardware is a fundamental component of polyfunctional robots, allowing them to switch easily between tasks. This modularity is achieved through interchangeable components, such as robotic arms that can be swapped for tools like welding torches or assembly grippers. Modular systems also enhance maintainability, as faulty components can be quickly replaced without affecting the entire system.

2. Advanced Sensors

Advanced sensors are crucial in providing polyfunctional robots with real-time environmental data. Technologies such as cameras, LIDAR (Light Detection and Ranging), and tactile sensors enable precise navigation and object identification. Tactile sensors offer feedback on touch and pressure, helping robots handle delicate objects. This sensory data is essential for tasks that require interaction with complex or dynamic environments.

3. Artificial Intelligence

Artificial intelligence (AI) is a key driver of polyfunctional robots’ adaptability. It allows robots to learn from experience, adjust to new situations, and optimize their actions based on feedback from sensors and other data sources. Similarly, Machine learning algorithms enable these robots to make adaptive decisions and continuously improve their performance. This capability is critical for tasks that require flexibility and the ability to respond to unforeseen challenges.

4. Cloud Connectivity & IoT Integration

Polyfunctional robots often integrate with cloud computing and the Internet of Things (IoT) to enhance their functionality. Cloud connectivity allows robots to access vast computational resources and shared knowledge bases, enabling them to learn from other robots and systems. IoT integration enables seamless communication with other devices and systems, facilitating coordinated actions in environments like smart factories or homes. This connectivity supports real-time data exchange, remote monitoring, and collaborative automation.

5. High-Precision Motion Control

High-precision motion control is essential for polyfunctional robots to execute complex tasks accurately. Robots achieve precise control in delicate operations through advanced motor drives and sophisticated algorithms. This capability is essential for applications like assembly, surgery, and precision manufacturing, where even minor errors can lead to significant consequences. High-precision motion control enhances safety by ensuring that robots operate within predetermined parameters.

These key components work together to enable robots to adapt to diverse tasks and environments efficiently. Next, we will discuss the different types of these robots and how they are tailored for specific environments and tasks.

Types of Polyfunctional Robots

Polyfunctional robots are designed to perform multiple tasks across various environments, and their classification is based on their form, functionality, and adaptability. Each type of polyfunctional robot is tailored for specific applications, leveraging advanced technologies to meet the demands of diverse industries. Below is an in-depth exploration of the key types of polyfunctional robots:

1. Humanoid Robots

Humanoid robots are designed to resemble the human body, often equipped with a head, torso, arms, and legs. These robots excel in environments where interaction with humans or tools designed for human use is required. They can carry out tasks that require human-like dexterity and interaction, such as recognizing human emotions and responding accordingly. Recent developments focus on enhancing bipedal locomotion and dexterity to improve their adaptability in unstructured environments.

2. Autonomous Robots

Autonomous robots operate independently without human intervention by leveraging AI-driven decision-making and advanced sensors. They can navigate complex environments, make decisions in real-time, and adapt to changing conditions. These robots rely on technologies such as LIDAR for mapping, computer vision for object detection, and machine learning for task optimization. Their ability to operate autonomously makes them highly efficient in environments where continuous operation is crucial.

3. Collaborative Robots (Cobots)

Cobots are designed to work alongside humans in shared workspaces while ensuring safety and efficiency. They can perform repetitive or physically demanding tasks while responding to human gestures or commands. Equipped with force sensors and AI, cobots can detect collisions and stop operations instantly to prevent accidents. Their ease of programming and deployment makes them highly versatile in dynamic environments.

4. Mobile Manipulators

Mobile manipulators combine a mobile base with a robotic arm, offering mobility and precision manipulation capabilities. These robots can navigate dynamic environments while performing tasks such as picking, placing, or assembling objects. Advanced navigation systems like 3D cameras and laser scanners enable obstacle avoidance, while AI ensures task adaptability. Their ability to move freely and manipulate objects makes them ideal for environments that require mobility and precision.

5. Soft Robots

Soft robots are built using flexible materials that mimic biological systems, making them suitable for delicate tasks requiring high adaptability. Unlike rigid ones, these robots can change their shape to handle delicate objects or move through tight spaces. Innovations in smart materials (e.g., hydrogels) enable these robots to respond to environmental stimuli such as temperature or light for enhanced functionality. Their flexibility allows them to perform tasks that would be challenging or impossible for traditional rigid robots.

These categories highlight polyfunctional robots’ diversity and ability to adapt across various environments. These robots harness AI, modularity, and advanced sensors to drive innovation and set new global standards for automation.

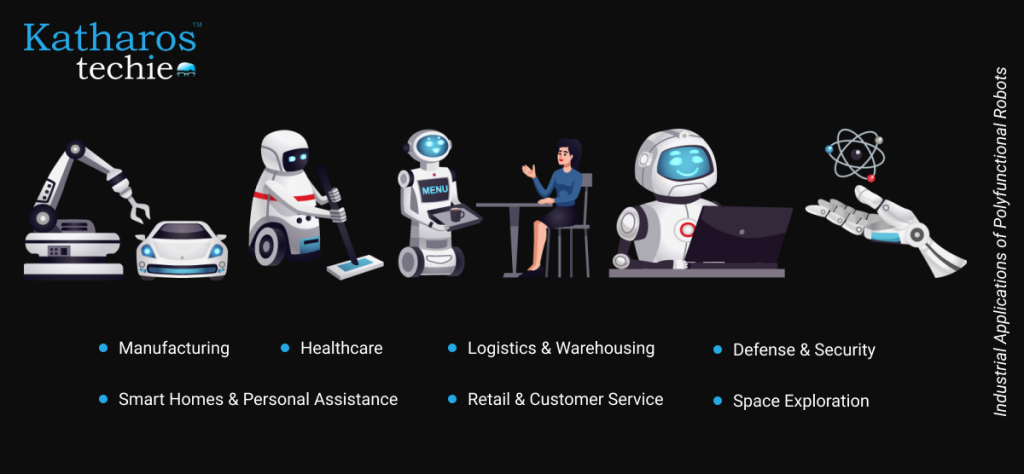

Industrial Applications of Polyfunctional Robots

Polyfunctional robots are reshaping industries by offering unmatched adaptability and efficiency. Their ability to perform diverse tasks with minimal reconfiguration makes them indispensable across various sectors. Below is an in-depth exploration of their applications:

1. Manufacturing

Polyfunctional robots have revolutionized manufacturing by automating multiple processes, including assembly, welding, painting, and quality control. These robots reduce downtime and enhance productivity by seamlessly switching between tasks. Baxter, developed by Rethink Robotics, can perform various assembly line tasks such as packing and sorting. Its modular design and ease of programming make it a valuable asset for manufacturers looking to optimize operations.

2. Healthcare

Polyfunctional robots support healthcare by assisting with surgeries, patient care, diagnostics, and hospital logistics. The da Vinci Surgical System exemplifies this versatility by enabling surgeons to perform minimally invasive procedures with exceptional precision. During the COVID-19 pandemic, robots like UV-disinfection robots played a critical role in minimizing human contact and preventing cross-contamination in hospitals.

3. Logistics & Warehousing

Polyfunctional robots transformed logistics and warehousing by automating inventory management, order fulfillment, and transportation. Amazon’s autonomous mobile robots (AMRs) efficiently navigate warehouses to pick, pack, and sort goods. Similarly, AutoStore’s robotic systems retrieve items from storage bins for rapid order fulfillment while collaborating with mobile robots for dynamic material handling.

4. Defense & Security

Defense applications of polyfunctional robots include surveillance, reconnaissance, bomb disposal, and rescue missions. For example, the PackBot, developed by iRobot, is equipped with modular payloads such as cameras and grippers to disarm explosives safely. Another example is the SWORDS robot, which has been used for urban warfare tasks like patrolling streets and securing checkpoints.

5. Smart Homes & Personal Assistance

In smart homes, polyfunctional robots handle tasks like cleaning, cooking, monitoring security, and providing personal assistance. The HIMTAE system integrates a multi-robot system for elderly care, combining a mobile assistant robot for emotional interaction with a manipulator robot that handles household chores. This system demonstrates the potential of polyfunctional robots to enhance daily living for individuals with reduced mobility.

6. Retail & Customer Service

Retail environments benefit from humanoid polyfunctional robots that assist customers and automate store operations. For instance, LoweBot, deployed by Lowe’s home improvement stores, helps customers locate products while providing information about inventory availability. Another example is Pepper, a humanoid robot that engages customers in retail outlets to boost sales and enhance customer experience.

7. Space Exploration

Polyfunctional robots play a crucial role in space exploration because they can adapt to challenging conditions. NASA’s Robonaut 2 (R2) is a humanoid robot built to help astronauts on the International Space Station (ISS) with maintenance, tool handling, and other duties. Similarly, ESA’s Justin robot demonstrates advanced manipulation capabilities for assembling structures on extraterrestrial surfaces.

These real-world examples highlight how polyfunctional robots are driving innovation across industries.

Polyfunctional robots represent a groundbreaking advancement in automation, offering unmatched versatility and adaptability across industries. With modular hardware, AI-driven intelligence, and advanced sensors, these robots seamlessly switch between tasks, meeting dynamic operational needs with precision and efficiency. Their ability to perform diverse roles, from manufacturing to personal assistance, makes them indispensable for modern enterprises. As industries face challenges like labor shortages and demand for hyper-automation, polyfunctional robots provide scalable and cost-effective solutions. Ready to transform your operations? Discover how polyfunctional robots can revolutionize your business today.